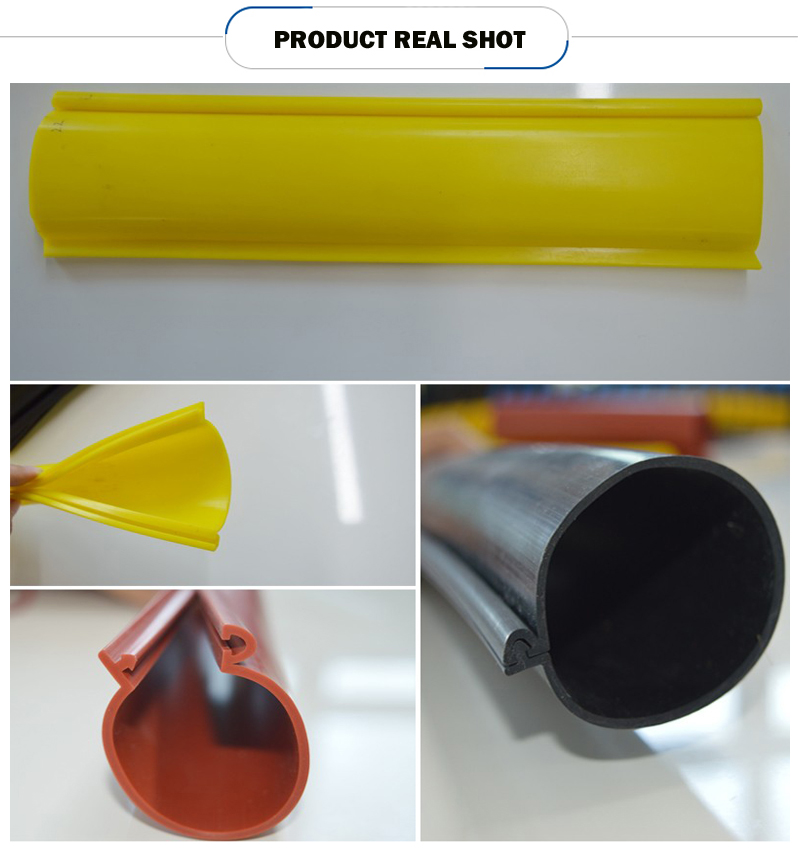

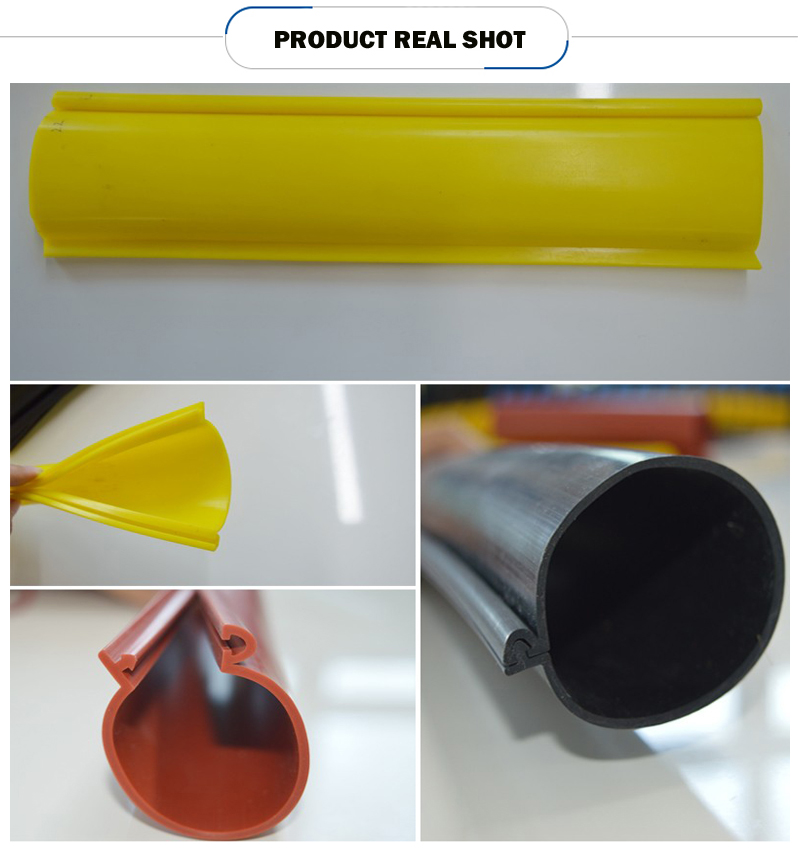

RUBNS-OLC High Voltage Overhead Line Silicone Rubber Cover Sleeve For Bare Conductor

The silicone rubber overhead line cover is our patented product. It is made of silicone rubber which is highly resistant to aging, erosion and corona. It can provide protection against electrical outages caused by incidental contact from tree branches or wildlife.

* Made of silicone rubber

* High resistance to aging and erosion

* Providing insulation for catenaries, droppers and conductors against contact from trees or wildlife

* Simple and fast installation, widely used in emergency repairs or temporary insulation protection of equipment

Technical Performance

Serial No. | Properties | Unit | Standard Data | Test Results | Test Methods |

1 | Electrical Strength Test | kV/mm | ≥20 | 22 | GB/T 1408.1-2006 |

2 | Volume Resistivity | Ω·cm | ≥1×1014 | 2×1014 | GB/T 1410-2006 |

3 | Dielectric Constant |

| 2~3 | 2.3 | GB/T 1409-2006 |

4 | Shore Hardness | A | 70±5 | 71 | GB/T 531 |

5 | Mechanical Properties |

|

|

| GB/T 528 |

5.1 | Before heat ageing |

|

|

|

| Tensile Strength | MPa | ≥4.0 | 5.5 |

| Elongation at break | % | ≥200 | 243 |

5.2 | After Heat ageing(180℃, 7d) | % | ±30 | 13 |

| Tensile Strength Change Elongation Change | % | ±30 | -22 |

6 | Low Temperature Elongation(-15℃, 2h) | % | ≥20 | 190 | GB/T 2951.4-1997 |

7 | Low Temperature Flexibility(-50℃, 4h) | - | No cracks | No cracks | UL224-2004 |

8 | High Temperature Crack Resistance(155℃, 2h) | - | No cracks | No cracks | GB/T2951.6-1997 |

Dimensions

LJ Stranded Wire Cross-sectional Area(Nominal) | O.D. Of LJ Stranded Wire(mm) | Silicone Rubber Sleeving Covers Models(mm) |

50 | 9.00 | Ф12 |

70 | 10.80 | Ф12 |

95 | 12.48 | Ф17 |

120 | 14.25 | Ф17 |

150 | 15.75 | Ф20 |

185 | 17.50 | Ф20 |

210 | 18.75 | Ф24.2 |

240 | 20.00 | Ф24.2 |

300 | 22.40 | Ф24.2 |

400 | 25.90 | Ф30 |

500 | 29.12 | Ф32 |

630 | 32.67 | Ф35 |

800 | 36.90 | Ф39.8 |

LGJ Stranded Wire& LGJF Stranded Wire Cross-sectional Area(Nominal) | O.D. Of LJ Stranded Wire(mm) | Silicone Rubber Sleeving Covers Models(mm) |

35 | -- | Ф12 |

50 | -- | Ф15.6 |

70/10 | 11.4 | Ф17 |

70/40 | 13.6 | Ф17 |

95/15 | 13.61 | Ф17 |

95/20 | 13.87 | Ф17 |

95/55 | 16 | Ф17 |

120/7 | 14.5 | Ф20 |

120/20 | 15.07 | Ф20 |

120/25 | 15.74 | Ф20 |

120/70 | 18 | Ф20 |

150/8 | 16 | Ф20 |

150/20 | 16.67 | Ф20 |

150/25 | 17.1 | Ф20 |

150/35 | 17.5 | Ф20 |

LGJJ-120 | 15.5 | Ф20 |

LGJJ-150 | 17.5 | Ф20 |

LGJQ-150 | 16 | Ф20 |

185/10 | 18 | Ф24.2 |

185/25 | 18.9 | Ф24.2 |

185/30 | 18.88 | Ф24.2 |

185/45 | 19.6 | Ф24.2 |

210/10 | 19 | Ф24.2 |

210/25 | 19.98 | Ф24.2 |

210/35 | 20.38 | Ф24.2 |

210/50 | 20.86 | Ф24.2 |

240/30 | 21.6 | Ф24.2 |

240/40 | 21.66 | Ф24.2 |

240/55 | 22.4 | Ф24.2 |

LGJJ-185 | 19.6 | Ф24.2 |

LGJJ-240 | 22.4 | Ф24.2 |

LGJQ-185 | 18.4 | Ф24.2 |

LGJQ-240 | 21.6 | Ф24.2 |

400/20 | 26.91 | Ф32 |

400/25 | 26.64 | Ф32 |

400/35 | 26.82 | Ф32 |

400/50 | 27.63 | Ф32 |

400/65 | 28 | Ф32 |

400/95 | 29.14 | Ф32 |

500/35 | 30 | Ф32 |

500/45 | 30 | Ф32 |

500/65 | 30.96 | Ф32 |

800/55 | 38.4 | Ф39.8 |

800/70 | 38.58 | Ф39.8 |

800/100 | 38.58 | Ф39.8 |

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factory Tour

CONTACT US

Contact person:Ms. Jessica Wu

Email : sales@heatshrinkmarket.com

WhatsApp/Wechat : 0086 -15850032094

ADDRESS:No.88 Huayuan Road, Aoxing Industrial Park, Mudu Town, Wuzhong District, Suzhou, China